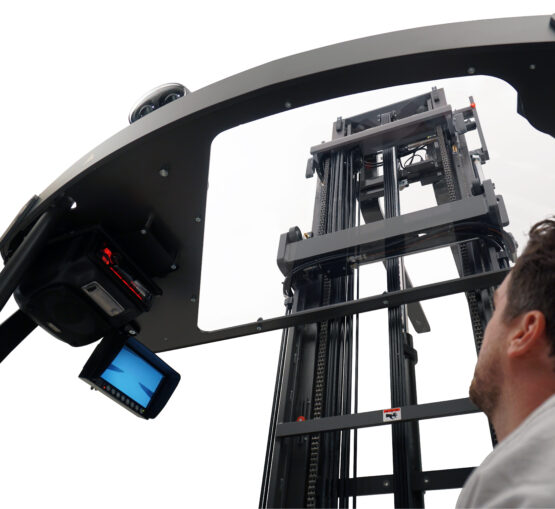

Tergo UMS, UHD, UHX

High storage reach truck

Lifting capacity 1600/2000/2500 kg

Lifting height up to 12.1 m

UMS / UHD / UHX high storage reach truck

A new generation of high storage UniCarriers reach trucks intended for works in difficult conditions offers the highest efficiency level of warehouse works.

Universal high storage UniCarriers UMS/UHD/UHX reach trucks designed around almost every task in a multi-shift storage system. Learn about the world’s most personalized high storage reach trucks. They are 100% dedicated to material transport operations.