WAREHOUSE AUTOMATION

Automated systems of internal transport

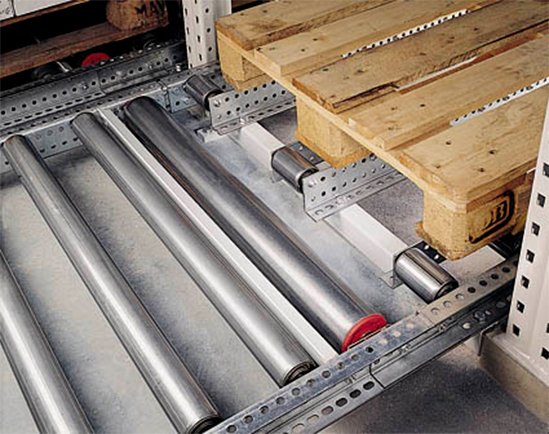

Automated systems of internal transport allow for self-operating transport of standardized loads in the building—also between different levels. Different types of loads can be transported, using our working platforms. Packages are transported via roller-driven and belt conveyors, lifts and gravity spiral conveyors. The main advantages of the solutions suggested above include their reliability, speed, and simplicity of operation. We create internal transport warehouse systems as well as manage them at the input of materials and goods to the company. Our systems work not only as standalone devices, but also as advanced system solutions. These systems connect the whole internal transport in a company with the logistics and storage into one uniform system.